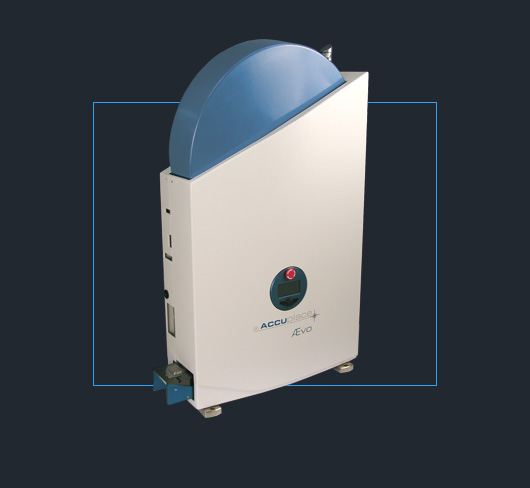

AccuPlace RM AEvo will help you:

- Cut setup and changeover time to less than one minute!

- Reduce maintenance and labor costs

- Increase throughput while reducing waste

- Significantly improve product quality

Print and apply even the tiniest film and label sizes, intricate die cut shapes and the most challenging adhesives… faster, easier and more accurately.

You’re under pressure to keep throughput high and defects low, plus minimize labor and operation costs. That’s where AEvo robot-mode Film Adhesive and Label Applicator with optional Print & Apply can help.

No other robotic adhesive and label machine gives you more flexibility to meet your customers’ requirements with ease and accuracy.

Whether you’re only applying standard or thermal labels or printing and applying, AEvo helps you meet demanding speed to market goals without sacrificing quality. Aevo’s printing option lets you print and apply a wide variety of labels with a placement accuracy of +/- .002” / 0.05mm.

AccuPlace standardized robot applicator machine design means you’ll get greater return on your investment. Unlike costly customized label machines, you’ll be able to take on more jobs with a single machine.

Incredible accuracy on even the smallest 2D-barcodes, graphics and more

AEvo thermal printing option lets you print at 300 and 600 dpi. It is perfect for 2D-barcodes and graphics on labels as small as 3mm x 3mm or smaller, which makes the RM-AEvo the most sought-after thermal label equipment on the market!

AccuPlace AEvo can improve your manufacturing efficiency and provide a lower cost of ownership.

- Patented peeling technology lets you peel and apply even the most difficult labels and components with accuracy and precision.

- Simplistic design makes operation easier for operators of all skill levels.

- Tool-less routine maintenance and chuck change

- Easy sensor setup and material threading

- One-click rewind and reel change are just a few of the time and money-saving features.

Film Adhesive and Label Feeder with optional Thermal Transfer Printer

RM Ævo is the new generation of accurate feeding equipment and optional printing up to a label or component size of 50 mm x 50 x mm x 5 mm / 2” x 2” .

Years of experience and thousands of applications placing complex die cut adhesive components have driven AccuPlace to develop a new standard in feeding technology which elevates state-of-the-art to a whole new level.