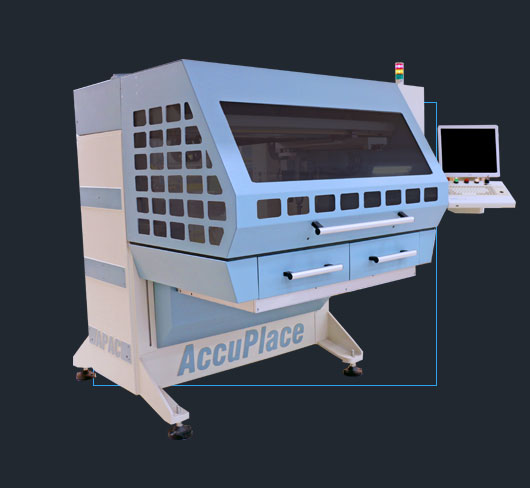

The AccuPlace APAC Industrial Robotic System

- Handles complex gasket placement cell processes including different orientations & multiple placements with our linear driven axes (X-Y plus optional Z and U).

- Easy integration with our adhesive component feeding systems.

- Fits your tight gasket placement cell tolerance requirements for industrial label and assembly with APAC integrated vision system.

- Precise gasket placement of delicate self-adhesive subcomponents, labels, complex adhesive patterns, optically clear adhesives, miniaturized parts and more.

- Elective automated tooling change-over expandss throughput by letting you run different part programs within the same day in the same gasket placement cell.

- Optional gasket placement cell accessories can be added to the APAC to facilitate material handling and material treatment such as conveyors, bowl-feeders, ionizers, air-purification systems and other operations.

APAC’s Proven Track Record

Any robot can automate and speed your process, but only the AccuPlace APAC gives you unparalleled automation speeds, precision and integration from a single standardized robot system—including the ability to feed up to four (4) different adhesive components.

That same manufacturing capability from custom designed equipment could cost you millions dollars. With AccuPlace APAC, one investment lets you easily manage today’s gasket placement cell subcomponent manufacturing needs and tomorrow’s challenges.

The AccuPlace innovative gantry robot APAC is the leading turnkey solution for fully automatic assembly tasks using adhesive components. Flexibility, reliability, and effortless product changeover are all requirements in today’s demanding marketplace. The APAC meets these market requirements by achieving the highest possible quality for your gasket placement cell.

APAC Works with AccuPlace Feeders

Standard linear driven X-Y axes, optional servo Z and U axes, a PC based control and powerful software build the most effective gasket placement cell tool on the market. The APAC can accommodate up to four AccuPlace feeders to allow the execution of complex assembly tasks.

Custom designed vacuum chucks are the only hardware required to changeover from one product to another product. This flexibility allows running of several product programs within the same day. Fully automatic tooling exchange is also possible.

Contact AccuPlace today to learn more about our industrial solutions from label application and printing, to fully-automated adhesive subcomponent assembly today.

APAC Works with Various Feeders

Pictured is an APAC working with a vibratory bowl feeder to orient plastic injected parts. With over a decade of experience in the field, APACs have been used is various applications alongside various other automation equipment. Maintaining integrity through reliable and accurate placement is the core tenet of APAC’s technology.

Below are more photos of the plastic injected parts queuing for APAC assembly. AccuPlace has a team of mechanical engineers who can design an APAC system to fit almost any application. Contact AccuPlace to hear what automation options you have to make your gasket placement cell a success.